How polymers are tested

The properties of plastics, by this name they mean a wide class of polymers, far exceed those of natural materials. But to determine the scope of the use of plastics, special tests are needed, which are carried out according to the developed standardized methods. The set of tests includes checks for:

- hardness;

- fragility;

- flammability;

- electrical resistance;

- light transmission;

- heat resistance.

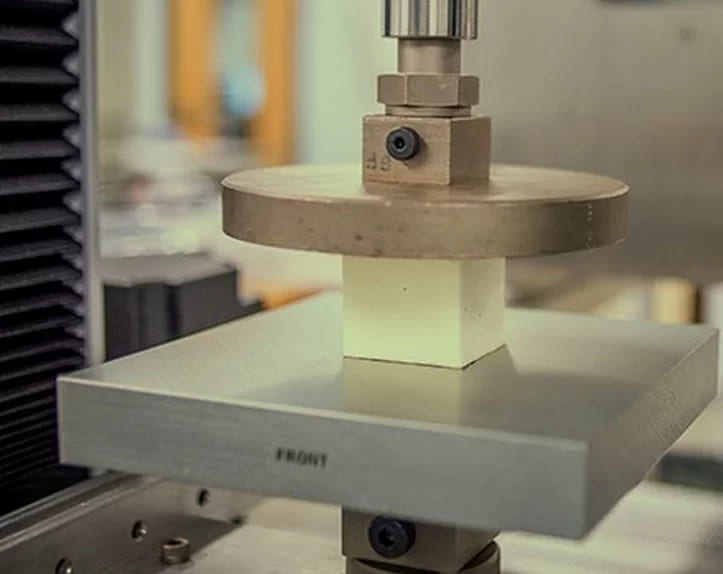

Strength and resistance to deformation are regulated by ISO R527 (DIN 53455, DIN 53457, ASTM D638M) standards, common to all countries where polymers are produced. For testing, standard laboratory facilities are used that issue data with a minimum degree of error.

In the process of testing, resistance to stretching, compression, flexibility, plasticity are determined. The stiffness of the polymer is determined by the principle of loading on a standard rod at a constant impact rate of 2 mm/min. In the same way, the modulus of elasticity is determined.

According to the results of testing polymers according to ISO and ASTM methods (USA and Canada), there is a certain correlation. But when choosing the appropriate polymer for the production of household or industrial parts, it is necessary to check compliance with tables and reference books.